The Great Laundry Mystery

You toss your favorite hoodie in the wash, and somehow it comes out looking like it belongs to your younger sibling. Sound familiar? Laundry disasters like this are practically a rite of adulthood. One cycle it’s fine, the next it’s tighter and shorter. You check the tag, blame the detergent—but the mystery keeps repeating itself. So, first, here are ten reasons your clothes seem to shrink no matter how careful you think you’re being.

1. Water Temperature Issues

High water temperatures cause fabric fibers to expand and contract repeatedly, which leads to noticeable shrinkage and distortion in shape. Hot water is especially harsh on delicate materials, weakening their structure and tightening the weave until garments lose their original fit.

Is washing clothes in cold water better that warm water? by WKYC Channel 3

Is washing clothes in cold water better that warm water? by WKYC Channel 3

2. Overdrying Cycles

Many consumers unknowingly damage their garments through overdrying, a common laundry mistake that forces excessive moisture from textile fibers. This harsh treatment causes materials to contract and become brittle, with natural fibers like cotton particularly susceptible to shrinkage and roughness.

LG Laundry - SteamFresh Cycle Dryer by HADCOAppliance

LG Laundry - SteamFresh Cycle Dryer by HADCOAppliance

3. Agitation During Washing

Mechanical agitation in washing machines causes fibers to rub, twist, and tighten, leading to noticeable shrinkage. As the material shifts and relaxes from its stretched state, it contracts and loses its original dimensions.

GE Appliances Laundry with Dual Action Agitator by GE Appliances

GE Appliances Laundry with Dual Action Agitator by GE Appliances

4. Improper Pre-Shrinking Treatments

Pre-shrinking helps fabrics stabilize by tightening the weave and increasing weft density, which minimizes shrinkage during later washes. Skipping this process can cause garments to contract noticeably after the first wash. This is why high-quality pieces labeled “sanforized” undergo pre-shrinking to preserve their fit and shape.

Pre-Shrink Fabrics Faster with this Technique by Fresh Press Patterns

Pre-Shrink Fabrics Faster with this Technique by Fresh Press Patterns

5. Inadequate Fabric Blending

When a fabric contains a high percentage of shrinkage-prone fibers such as cotton or spandex, it’s more likely to contract after washing. In contrast, materials with fewer synthetic stabilizers lack balance, allowing natural fibers to tighten and reduce overall garment size.

Buy Better Clothes: Fabric Blends Explained by Laura VonV

Buy Better Clothes: Fabric Blends Explained by Laura VonV

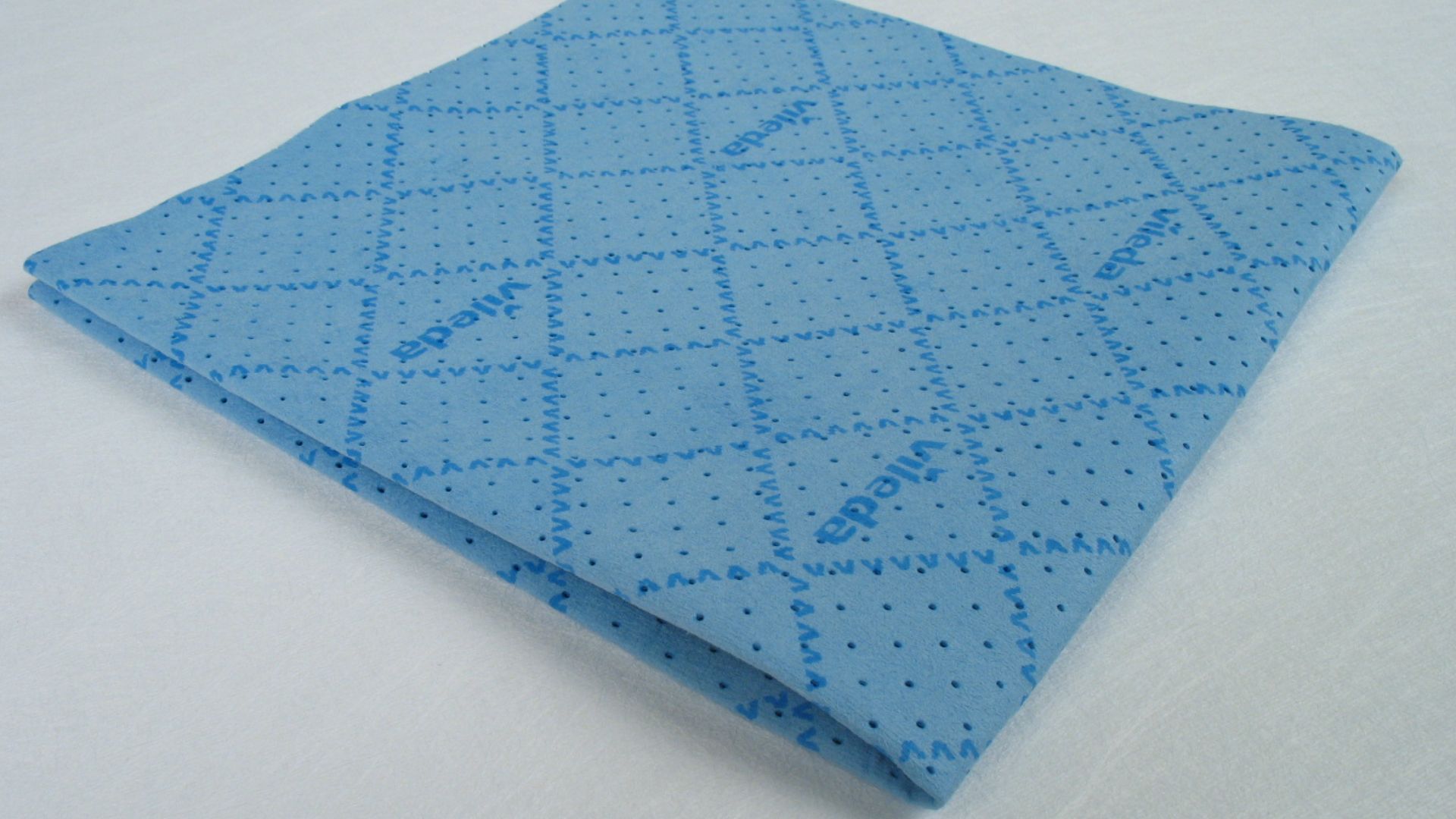

6. Wrong Wash Cycle Selection

Choosing an unsuitable wash cycle increases the likelihood of shrinkage. Harsh or extended cycles expose fabrics to excessive motion and friction, forcing fibers to contract. Delicate materials are especially vulnerable, as they get reduced after just a few washes.

[Front load washer] SideKick™ - Cycle selection by LG Canada Support

[Front load washer] SideKick™ - Cycle selection by LG Canada Support

7. High Spin Speed Effects

Excessively high spin speeds strain fabric fibers, forcing them to twist and contract under intense centrifugal force. This mechanical stress causes tighter weaves and smaller dimensions, particularly in cotton and wool garments. Over time, repeated high-speed spinning compounds the effect, leading to irreversible shrinkage.

8. Steam Or Ironing Heat Exposure

Contrary to the belief that ironing is purely cosmetic, it fundamentally alters fabric at the fiber level. When exposed to steam or high heat, fibers undergo structural reorganization and contraction, potentially causing permanent shrinkage.

9. Improper Storage Conditions

Poor storage environments with excess moisture or humidity can gradually trigger fiber contraction, leading to mild but lasting shrinkage. As fabrics repeatedly absorb and release moisture, internal tension shifts within the weave, causing fibers to draw closer together and subtly alter the garment’s original proportions.

10. Lack Of Fabric Relaxation Time

Here's a witty twist: while washing clothes might get them clean, it also leaves textile fibers more wound up than a cat at a dog show. This internal tension desperately needs relaxation time to unwind and stabilize—think spa day for fabrics.

Now, let’s talk about the fabrics that barely shrink.

1. Polyester

Polyester's exceptional resistance to acids, alkalis, and industrial chemicals makes it a manufacturing powerhouse, engineered from polyethylene terephthalate (PET) for maximum production efficiency. This translates directly to consumer advantages: dimensional stability that prevents stretching and shrinking.

2. Nylon

Before nylon emerged as the first fully petrochemical synthetic fiber, manufacturers struggled to find materials that combined strength with stability. The invention marked a turning point in textiles, offering remarkable tensile strength, outstanding abrasion resistance, and dependable shape retention through repeated use.

Nylon fabric by Chmtextile@com

Nylon fabric by Chmtextile@com

3. Spandex

Unlike natural fibers that lose their shape after stretching, spandex stands as a triumph of synthetic innovation. Both natural and synthetic fibers can shrink under high heat, yet spandex’s capacity to stretch up to five times its length and retain form makes it unbeatable in performance wear and everyday clothing.

U.S. Air Force photo/Mike Kaplan on Wikimedia

U.S. Air Force photo/Mike Kaplan on Wikimedia

4. Acrylic

Acrylic’s effortless maintenance begins with its engineered resistance to moths, oils, and chemicals, making care routines simple and stress-free. The fiber retains dimensional stability through repeated washing and delivers reliable performance in lightweight, adaptable forms.

Outdoor Sunshade Acrylic Fabric by SICHUAN GROUPEVE CO.,LTD

Outdoor Sunshade Acrylic Fabric by SICHUAN GROUPEVE CO.,LTD

5. Microfiber

Traditional fabrics frustrate users with persistent shrinkage, lengthy drying times, and ineffective cleaning performance. Microfiber technology resolves these challenges through its engineered synthetic construction and resists deformation through repeated washing.

6. Lyocell (Tencel)

At the molecular level, Lyocell's exceptionally smooth fiber structure translates into remarkable skin comfort, making it ideal for sensitive skin. This advanced material, produced through a 99% solvent-recycling closed-loop process, delivers impressive dimensional stability with minimal 3-5% shrinkage.

7. Rayon

Through a sophisticated transformation process, cellulose fibers are regenerated into rayon, which is then subjected to specialized pre-shrinking treatments. It is this dual-stage manufacturing that ensures the fabric maintains dimensional stability after washing while preserving its characteristic silk-like drape.

How to Sew With Rayon | Fabric Guide by Seamwork

How to Sew With Rayon | Fabric Guide by Seamwork

8. Bamboo Fabric

Harnessing bamboo's remarkable renewable growth cycle, this eco-conscious fabric represents sustainable luxury without compromise. Its inherent silky softness and hypoallergenic, odor-resistant properties deliver premium performance, while simple care protocols preserve its integrity despite heat sensitivity.

Bamboo T Shirts by Unitrends by Unitrends Clothing

Bamboo T Shirts by Unitrends by Unitrends Clothing

9. Modal

Through advanced cellulose processing, beech tree pulp is transformed into modal rayon—a refined achievement in modern textile engineering. The resulting fiber offers outstanding moisture absorbency, impressive dye retention that preserves color vibrancy, and natural resistance to shrinkage.

Modal Fabric Video by Core Fabrics

Modal Fabric Video by Core Fabrics

10. Cashmere (Treated)

Unlike untreated cashmere, which traditionally risks shrinkage, treated variants maintain the signature fineness of goat undercoat fibers while offering superior dimensional stability. This preserves the natural properties that make cashmere finer than human hair.

Invisible Mending: Repairing a hole in a cashmere sweater by Allude

Invisible Mending: Repairing a hole in a cashmere sweater by Allude